Overview Warehouse Management System

- Rajesh Sharma

- Feb 9, 2023

- 4 min read

Warehouse Management System

What is Warehouse?

A Warehouse is a building for storing goods. Warehouses are used by manufacturers, importers, exporters, wholesalers, transport, customs etc. they are usually large plain buildings in industrial parks on the outskirts of cities, town, villages.

A large, small or medium size buildings for storing things before they sold, used or sent out to shops.

A warehouse is a commercial building generally used for storage goods warehousing is the process of proper storage and handling of goods and cargo using scientific methods in warehouse and making them available easily and smoothly when needed.

Types of Warehouse

1. Simple inventory warehouse

In this warehouse process is simple inventory maintain

2. Store Warehouse

Store is in house facility to help manufacturing activities. Such as incoming and in some cases outgoing also stored in stores, for example, raw Material store, electrical items stores, mechanical items and machine part stores, Finished goods stores etc.

Raw material stores

Electrical Parts Store

Machine Parts Stores

Finished goods stores

3. Distribution Center

Distribution center for a set of products is a warehouse or other specialized building with refrigeration or air conditioning which is stocked.

4. Pick, Pack and Ship Warehouse

5. Cold Storage

6. ON-Demand storage

7. Bonded Warehouse

8. Smart Warehouse

Classification of Warehouse

From process point of view warehouse can be classified as

1. Basic Warehouse

2. Big Warehouse

Multiple truck coming with multiple products in the warehouse

Multiple truck loading and unloading every day in warehouse.

The material storing and high rack storage, rack storage and open storage

Need appropriate put-away to store the materials in respective storage bins

Need appropriate picking strategy to pick the material to load the truck to deliver the customer

Multiple resources and manpower are involve to in warehouse activities like unloading the truck and keep in respective storage bin, and pick the delivery quantity and load in to truck for outbound delivery.

Need to manage inventory of incoming and outgoing materials, and available stock of materials in warehouse.

Maintain right product deliver to the customer right time.

3. Complex Warehouse

Why do we required IT & Software solution for Warehouse Management?

Inventory Management incoming, outgoing, and stocks of products with in warehouse

Receiving of goods and put away of goods in dedicated place (storage bin) to store within warehouse

Sorting process to optimize warehouse

Loading in time the outbound deliveries goods

Movement and storage of goods in warehouse

Location management

Picking strategy to for customer delivery order

Packing of goods for customer delivery order

Invoicing and dispatch activities

Inventory reconciliation

An effective and right solution for a warehouse depends upon business requirement, and volume, and number of process going on in the warehouse.

Right solution need to suggest to the business fulfill their requirements for smooth operation of their warehouses.

Most Important Warehouse Processes

Goods Receiving

Put-away of goods

Picking

Packing

Dispatching

Shipping

Kitting and de-kitting

Inventory tracking

FIFO/LIFO/FEFO picking strategies

Value added services

Goods returns from customers

Reporting and analytics

Available Warehouse Management Solution in Market

There are hundreds of warehouse management solutions available in the market, here is popular one are given below.

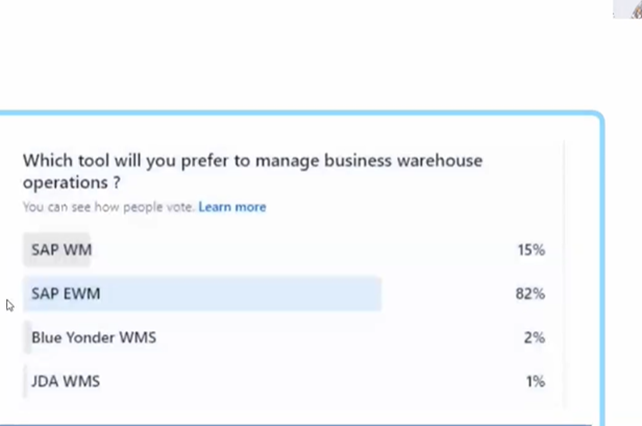

Survey was carried out regarding prefer WMS system the results was as below

What Solution SAP Has?

1. SAP Inventory Management

SAP Inventory management use

Manage stocks of merchandise on a quantity and value basis

Plan, enter and provide evidence of all goods movements

In SAP Inventory Management mange stocks on a site and storage location level, and can assign each site a number of storage location, can link warehouse management to inventory management.

Inventory management enables you to have an overview of your current stock status all time.

A material document created for every transaction

Complete audit trail for all goods movements

Goods movements are valuated automatically and results updates on the financial accounting stock accounts.

2. SAP Warehouse Management

The SAP Warehouse management application is fully integrated into SAP R/3 system.

Integrated with Material Management

Integrated with Sales & distribution

Integrated with Quality Management

The material document created for the material movement generated either in MM, SD, or QM modules. For all Goods receipt (GR), from other vendors and plants, document generated in MM module. For Goods Issue (GI) for either to production, others plants, will be generated in MM module.

As quality management is active in the organization, all materials will pass the quality inspection process during GR and GI and post change document will be generated during put away or stock removal of material in warehouse.

Warehouse Management (WM) helps to identify stock status of materials at bin level. It is tool to assist in processing all goods movements and maintaining inventories.

WM Process flow

Define and manage complex warehouse structure

Optimize material flow using advanced put-away and picking techniques.

Process, goods receipts, goods issues, and stock transfers quickly and easily.

3. SAP Extended Warehouse Management

SAP Extended Warehouse Management is a part of SAP Supply chain management like warehoused management system, but it provides more robust and advanced features to manage key activities in a warehouse.

SAP EWM is used to efficiently manage inventory in a warehouse and for supporting processing of goods movement. It allows any company to control their warehouse’s inbound and outbound processes and movement of goods in the warehouse.

SAP EWM is similar to warehouse management system but it provides more features like picking, put away, RF framework, Warehouse Structure and more flexible options to manage warehouse functions.

You can create new elements like activity area, resources, labor management and work centers in SAP EWM which were not available in WM.

SAP EWM provides more a robust solution to manage warehouse functions in an organization.

Key Features Comparison SAP IM/WM/EWM Solutions

What we can adopt in S/4HANA

SAP Inventory Management (IM)

SAP Warehouse Management (WM) (sunset by 2025/2027

SAP S/4HANA Embedded Extended Warehouse Management (Centralized EWM)

Basic Embedded Extended Warehouse Management

Advanced Embedded Extended Warehouse Management

4. Decentralized EWM SCM EWM or S/4HANA EWM

SAP ERP ECC System separate Set of Box, SCM EWM or S/4HANA EWM on separate set of box

Advantage of SAP S/4HANA Embedded EWM

Simplified system land scape. An embedded EWM solution drastically simplifies the IT landscape

Seamless Integration

Accelerated implementation

Flexible licenses

Real-time insights

Less data duplication

Limitation of SAP S/4HANA Embedded EWM

With Embedded EWM it is not possible to integrate with storage locations in other SAP ERP system

The embedded EWM solution is not adaptable with multiple warehouse pr with large material flow system traffic.

It cannot keep operational in case of ERP system down.

Rajesh Sharma

SAP WM/EWM Functional Consultant

§ Linked in profile: https://www.linkedin.com/in/rajesh-sharma-3a565821/

§ Twitter: RajeshS98151512/RAJESH SHARMA@RAJESHS21287609

§ SAP Blogs: https://www.sastrageek.com/blog

EPS Machine EPS Cutting…

EPS Machine Eps Raw…

EPS Machine EPS Recycling…

EPS Machine EPS Mould;

EPS Machine EPS Block…

EPP Machine EPP Shape…

EPTU Machine ETPU Moulding…

EPS Machine Aging Silo…

EPTU Machine ETPU Moulding…

EPS Machine EPS and…

EPS Machine EPS and…

AEON MINING AEON MINING

AEON MINING AEON MINING

KSD Miner KSD Miner

KSD Miner KSD Miner

BCH Miner BCH Miner

BCH Miner BCH Miner