Activity Area and Storage Type Search Sequence for Complex Inbound

- Rajesh Sharma

- Jul 20, 2024

- 13 min read

Activity Area and Storage Type, Storage Section, Search Sequence, and Storage Bin for Complex Inbound Process

This blog will discuss steps to configure Activity Area and Storage Type Search Sequence for Complex Inbound

Configuration Steps

1.1 Define Activities

Step 1: Click on New Entries

Step 2: Enter the Warehouse Number, Define the Activity Description and Warehouse Process Category, and Save

1.2 Define Activity Area

In this Customizing activity, you can define your activity areas. You can define as many activity areas as you require for each warehouse number.

Activities

Define an activity area for your warehouse and add a description.

If you want to join activity areas together, select the Joined Together checkbox. For more information, see Join Activity Areas Together and Joined Together.

If you want Extended Warehouse Management to create activity areas and sort sequences automatically, use the report /SCWM/R_AREA_LGTYP_CREATE. This report creates the sort sequences and creates the activity areas 1:1 from the storage types. This means that in Customizing, you only need to define activities. For more information, see /SCWM/R_AREA_LGTYP_CREATE and Define Activities for Activity Areas.

Step 1: Click on New Entries

Step 2: Enter Storage Type (Activity Area) and Description

1.3 Assign Storage Bins to Activity Area

In this Customizing activity, you can assign storage bins to activity areas. You can assign storage bins explicitly or implicitly.

Prerequisites

You have defined storage bin identifiers for the storage bin structures. For more information, see Define Storage Bin Identifiers for Storage Bin Structures.

You have defined storage bins for the warehouse structure or have manually entered the storage bin identifiers in the database. For more information, see Define Storage Bin Structure and Edit Storage Bin.

Activities

Assign the storage bins to activity areas using one of the following options:

Explicitly enter all parts of the storage bins.

To do this, enter the intervals for your individual storage bin parts (such as Aisle Start or Aisle End). Make these entries for all storage bin parts in the relevant storage bins, including the storage bin subdivisions. You have defined the storage bins in the storage bin structure. The system only assigns the relevant storage bins to the activity area if they are completely specified.

If you want to define your storage bins as a consolidation group, make an entry in the Cons. Grp field.

Implicitly enter the storage type.

Enter only the storage type. You can leave all the remaining fields empty. The system specifies the storage bins using the storage type and assigns all storage bins within this storage type to the activity area.

Step 1: Click on New Entries

Step 2: Enter Storage Type (Activity Area), Storage Type, Consolidation Group

1.4 Define Sort Sequence for Activity Areas

In this Customizing activity, you can define the sorting rules within an activity area for all activities except cross-line stock put-away. If required, you define sort rules for cross-line stock put-away under Define Sort Sequence for Cross-Line Stock Putaway.

Assign a sort sequence to each Storage Bins to Activity Areas entry. You can assign sort sequences explicitly or implicitly.

Prerequisites

Activities

Assign a sort sequence to a storage bin assignment for an activity area, using one of the following options:

Explicitly enter the sorting

Enter the criteria (sorting, path direction, pick mode) for your storage bin parts.

Implicitly enter the sorting

Enter only the storage type. You can leave all remaining fields blank. The system sorts by storage bin name in ascending order.

After you've executed this activity, you can use report /SCWM/TLAGS_CREATE to create the sorting in the database.

1.5 Storage Bin Sorting

Step 1: Enter Warehouse Number

Step 2: Enter Activity Area, Delete the Existing one then Execute for New Sorting

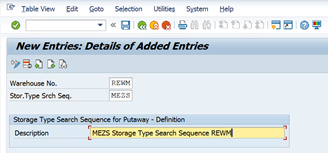

1.5 Define Storage Type Search Sequence

You can define storage-type search sequences for put-away. Storage-type search sequences are required for the put-away process and for warehouse rearrangement.

If you work with an automatic warehouse, you can instead use the Customizing activity Define Aisles and Levels Accessible by Communication Point in Customizing for Extended Warehouse Management under Material Flow System (MFS) -> Master Data. On the launch-pad, you can also choose Extended Warehouse Management -> Master Data -> Material Flow System (MFS) -> Define Aisles and Levels for MFS Resources. Alternatively, you can use transaction /SCWM/MFS_RSRC_AISLE.

Put-away process

The storage type search sequence in the put-away process specifies in which storage types the system searches for destination storage bins. The system creates a preference list that contains the sequence of storage types and storage type groups it should search with priority for destination storage bins.

Later, in the Customizing activity Specify Storage Type Search Sequence for Put-away, you specify the determination of the search sequences.

Slotting

The storage type search sequence in slotting specifies which storage types are possible for a product. The system checks these storage types for suitability according to the rules defined for slotting.

Later, in the Customizing activity Define Put-away Control Indicator, you assign a storage type search sequence (potential storage types) to a put-away control indicator.

Step 1: Click on New Entries

Step 2: Enter Warehouse Number, Storage Type Search Sequence, and Description and save

1.7 Assign Storage Type to Storage Type Search Sequence

In this Customizing activity, you assign the required storage types to the storage type search sequences that you have created in the Customizing activity Define Storage Type Search Sequence for Put-away.

Activities

Put-away process

Enter the storage types in which the system should search for destination storage bins for the relevant storage type search sequence.

Slotting

Enter the storage types slotting should search for the relevant search sequence.

Step 1: Click on New Entries

Step 2: Enter Warehouse Number, Storage Type Search Sequence and Storage Type and Save.

1.8 Define Put-away Control Indicator

You can define put-away control indicators. You can use put-away control indicators to control that during put-away, specific products are put away into specific storage types/storage type groups with priority.

You can also assign a storage-type search sequence to the put-away control indicator. This storage-type search sequence is not relevant for determining destination data during warehouse task creation.

Activities

1. Classify your products according to specific criteria, for example, small parts or products for the bulk storage area.

2. Create your put-away control indicators with corresponding descriptions.

Step 1: Click on New Entries

Step 2: Enter Warehouse Number, Put-away Control, Description and Save

1.9 Create Storage Section Indicator

You can define storage section indicators.

The storage section indicator divides products into groups with the same characteristic attributes, for the put-away process in various storage sections. You can use the storage section indicator to assign specific product groups to specific storage section search sequences.

The storage section indicator:

Can be defined manually in the product master

Can be determined automatically by slotting

Prerequisites

Standard settings

In the SAP standard system, the examples are set up in warehouse number 0001.

Activities

1. Decide whether you want to use the storage section search.

2. Classify your products according to certain criteria, for example, fast-moving items or slow-moving items.

3. Create your storage section indicators with corresponding descriptions.

Step 1: Click on New Entries

Step 2: Enter Warehouse Number, Storage Section Indicator, Description and save

1.10 Maintain Storage Section Search Sequence

You can maintain storage section search sequences. You need storage section search sequences for determining storage sections. This occurs as follows:

1. To find a suitable storage section, the system first needs a suitable storage type.

The system determines the storage type based on the Customizing activities Define the Storage Type Search Sequence for Put-away and Specify Storage Type Search Sequence for Put-away.

2. The system then needs the storage section in which it is to put away the product.

The relevant storage section search sequence provides this information. You have created the preference list for the storage sections for putaway in this Customizing activity. The system first searches for a storage bin in the first storage section. If it does not find a storage bin there, the system searches in the second storage section, and so on.

3. You can also influence storage section searches using the following indicators:

Storage section indicators from the product master

Hazard ratings 1 and 2

The system only considers the hazard ratings 1 and 2 if you have activated them in hazardous substance management.

4. You can manually specify storage bins for put-away. In this case, the system checks whether the specified storage bin lies in a storage section in which the product can be put away.

Prerequisites

You have activated the storage section check in Storage Section Check.

You have defined storage section indicators Create Storage Section Indicators.

Activities

Configure the parameters required for storage section searches in the following order:

1. Storage section indicators

You can assign a storage section indicator to any product. By using this indicator, you have the option to put away products in a particular storage section.

2. Storage section search

For each storage section indicator, you can store a list of storage sections in each storage type.

3. Storage section check

Activate the storage section check.

Step 1: Click on New Entries

Step 2: Enter Warehouse Number, Storage Type, Storage Section Indicator, Storage Section and save

1.11 Maintain Storage Section Check

You can define the storage section search and check and the hazardous substance check for each storage type.

Storage Section Search and Storage Section Check

When the storage section search and storage section check is active, goods are put away only in storage sections that are found as storage section search sequences in the storage section search. A predefined storage section is checked against the particular storage section search sequence.

Storage Section Search

When the storage section search is active, goods are put away in the storage sections that were found as storage section search sequences in the storage section search. A predefined storage section is accepted without a check.

If neither the storage section search nor the storage section check is active, all the storage sections are allowed and are accepted without a check.

Hazardous Substance Check

Hazardous Substance Check at Storage Type Level

When the hazardous substance check at storage type level is active, goods are only put away in a storage type if hazard ratings 1 and 2 of the stock to be put away are permitted for the destination storage type.

Hazardous Substance Check at Storage Section Level

When the hazardous substance check at storage section level is active, goods are only put away if a storage section search sequence for the hazard ratings 1 and 2 of the stock to be put away was defined in the storage section search.

Activities

1. Decide whether you want to use the storage section search and check.

2. Decide whether you want to use the hazardous substance check.

3. Make the relevant settings for each storage type.

Step 1: Click on New Entries

Step 2: Select Warehouse Number Storage Type, Check Storage Section from drop down and save

1.12 Specifies Storage Type Search Sequence for Put-away

You can specify the storage type search for the storage type search sequence during put-away.

The storage type search sequence defines the storage types in which the system searches for destination storage bins, and the sequence in which they are sorted or prioritized.

The storage type search that you define here refers to a storage type search sequence (storage types in which the system searches and in which sequence) and to a put-away rule.

If you work with an automatic warehouse, you can instead use the Customizing activity Define Aisles and Levels Accessible by Communication Point in Customizing for Extended Warehouse Management under Material Flow System (MFS) -> Master Data. On the launch-pad, you can also choose Extended Warehouse Management -> Master Data -> Material Flow System (MFS) -> Define Aisles and Levels for MFS Resources. Alternatively, you can use transaction /SCWM/MFS_RSRC_AISLE.

Activities

Define the storage type search for your storage type search sequence for put-away.

You can use the following indicators to influence the storage type search:

Put-away control indicator (from the product master)

Warehouse process type

Quantity classification group for the warehouse

Stock type or stock type group

Special reference stock type

Stock usage

Party entitled to dispose of stock

Hazard rating 1

Hazard rating 2

Step 1: Click on New Entries

Step 2: Enter the Warehouse Number, Put-away Control Indicator, Warehouse Process type, Storage Type Search Sequence and Save

1.13 Optimize Access Strategy for Storage Type Search Sequence for Put-away

You can optimize the access strategy for storage-type searches during put-away.

Various indicators influence the storage type search. If you use the putaway strategies from the product master, and the products appear with different stock types or are managed in special stocks (such as sales order stock), then the number of required entries in the storage types search table can be overly large.

To reduce the number of entries, you can define an access strategy for the storage type search table. Using this access strategy, the system searches the relevant entries as follows in the storage type search table:

1. The system checks whether there is a group assignment for the following entries

Warehouse process type

Quantity classifier in the warehouse

Stock type

If this is the case, the system uses the group to read the storage type search table.

2. The system first attempts to read a fully qualified entry, in other words, an entry with all the relevant indicators from the product master and - where available - the dangerous goods master, in the storage type search table.

3. If the system cannot find an entry in the storage type search using the fully qualified access, it attempts a generic access according to the optimization maintained in this activity. During a generic access, the system only reads qualified attributes that are set in the relevant data record in the optimization table. All other attributes are initialized. In other words, the system only finds data records where these attributes are also initial.

Activities

Create the necessary entries if you want to optimize the access strategy for storage type searches during put-away.

1.14 Define Storage Bin Type

You can define your storage bin types.

You can divide your storage bins into groups according to their physical attributes (for example, large bins, or small bins).

During slotting, you can have the system determine a preferred storage bin type.

In combination with the handling unit type, a suitable storage bin is suggested to you during put-away.

Activities

1. Decide whether you want to use storage bin type determination or slotting.

2. Create your storage bin types with the relevant descriptions.

Step 1: Click On New Entries

Step 2: Enter Warehouse Number, Storage Bin Type, Description and save

1.15 Assign Storage Type to Storage Bin Type

You can assign storage bin types to a combination of warehouse number and storage type. As a result, the performance during storage bin determination improves.

If there is at least one storage bin type assigned to a storage type, you can't create storage bins without a storage bin type in this storage type.

If you are assigning storage bin types to a storage type for which you have already created storage bins, you must ensure that the data is consistent. Otherwise storage bins without assigned storage bin types will not be considered during storage bin determination.

Activities

You have the following options:

No assignment: Storage bins of this storage type can contain any storage bin type that is available, or they can contain no storage bin type.

At least one storage bin type assigned to a storage type: Storage bins of this storage type are restricted to using one of the assigned storage bin types.

Step 1: Click on New Entries

Step 2: Enter Warehouse Number, Storage Type, Storage Bin type and save.

1.16 Define HU Type and Assign HU Type Group

In this Customizing activity, you specify which of the generally available handling unit types (HU types) you want to use or permit in your warehouse.

You can also assign the following:

Unit-of-measure load category for workload evaluations

You can assign a unit-of-measure load category for workload evaluations to each HU type.

HU type group

You can assign each HU type to a HU type group that you defined in Customizing activity Define HU Type Groups.

An HU type can only belong to one HU type group.

Prerequisites

You have defined HU types (where necessary in an enterprise management system, for example, SAP S/4HANA or SAP ERP).

Activities

Assign the HU types that you want to use or permit in your warehouse number to this warehouse number

Step 1: Click on New Entries

Step 2: Enter HU Type and Description and Save

1.17 Define HU Type for Each Storage Type

In this Customizing activity, you can define for each storage type the permitted handling unit types (HU types) that are used in a warehouse activity such as put-away. Alternatively, you can also specify for each storage type valid HU type group.

Extended Warehouse Management (EWM) can manage storage bins of different sizes within a storage type. The storage bins are determined using storage bin type determination, for example.

It consists of:

HU type check

Storage bin type check

Note: The HU type check and the storage bin type check are only performed if you have activated the attribute HU Type Check for the storage type in Customizing activity Define Storage Types.

The checks consist of the following steps:

1. During put-away, it is usually known with which HU type the product is to be put away. You either enter this information manually or it is defined in the product master. Alternatively, the information is determined in the put-away process.

2. The system checks whether the HU type to be put away is allowed to be put away in the storage type that storage type determination has found.

You have defined for each storage type which HU types are allowed to be used within this storage type. You can assign a maximum of 30 HU types for each storage type.

3. The system then searches for a suitable destination storage bin using the storage behavior/put-away rules. It only finds storage bins that are allowed for the storage type that has been determined.

For this, you have assigned a storage bin type to each storage bin in the master data.

For each HU type, the permitted storage bin types are used to check whether a storage bin is allowed.

The system restricts its search for a destination storage bin to these permitted storage bin types, whereby it goes through the storage bin types sequentially in the order of the entries in this table (in the standard system).

4. If you enter the storage bin manually during put-away, the system checks whether the HU type can be used at the relevant storage bin.

Activities

To use storage bin type determination, you must make the following settings in the order specified:

1. Divide your storage bins into groups (storage bin types), for example, large bins or small bins.

2. Check your storage bin master data and add any missing storage bin types.

3. Classify your HUs according to HU types (for example, according to pallet types).

4. If you have not done so already, create palletization data as packing instructions for your products.

5. In this activity, assign HU types to storage types. By doing this, you define for each storage type which HU types are allowed to be put away within this storage type.

6. Assign HU types to storage bin types. By doing this, you define which HU types are allowed to be put away for each storage bin type.

7. Activate the HU type check for the required storage types.

Step 1: Click on New Entries

Step 2: Enter Warehouse Number, Storage type and HU Type and Save

1.18 Define HU Type for Each Storage Bin Type

In this Customizing activity, you define the handling unit types (HU types) allowed in a storage bin type for put-away. These definitions are used by storage bin type determination.

Using the allowed storage bin types for each HU type, the system checks whether a storage bin can be used.

The search for a destination storage bin is restricted to these allowed storage bin types, where the system runs through the storage bin types in sequence, according to the sequence of the entries in this table.

You can define the allowed bin types as follows:

Globally for each warehouse number, by leaving the storage type blank

For each warehouse number and storage type

During put-away, the system first uses the storage type determined to perform an access with a qualified storage type. If the system does not find a data record, it performs an access with an initial storage type.

Prerequisites

You have activated the HU Type Check for the relevant storage type in the Customizing activity Define Storage Type. This check is not dependent on the put-away behavior and put-away rules.

Step 1: Click on New Entries

Step 2: Enter Warehouse number, Storage Type, HU Type, Bin Type

1.19 Maintain Put-away Control Indicator, Storage Section Indicator in Warehouse Product Master

Step 1: Enter Material, Warehouse Number, Party Entitled to Dispose, Click on Change

Step 2: Click on Warehouse Data tab, enter Put-away control indicator, storage section indicator, and save

Conclusion

The above steps must be followed to configure the Activity area, Storage Type Search Sequence, Storage Section Search Sequence and Storage Bin Determination for complex Inbound Process using Process Oriented Storage Control in SAP Extended Warehouse Management.

Rajesh Sharma

SAP WM/EWM Functional Consultant

§ Linked in profile: https://www.linkedin.com/in/rajesh-sharma-204910278/

§ Twitter: RajeshS98151512/ RAJESH SHARMA@RAJESHS21287609

§ SAP Blogs: https://www.sastrageek.com/blog

EPS Machine EPS Cutting…

EPS Machine Eps Raw…

EPS Machine EPS Recycling…

EPS Machine EPS Mould;

EPS Machine EPS Block…

EPP Machine EPP Shape…

EPTU Machine ETPU Moulding…

EPS Machine Aging Silo…

EPTU Machine ETPU Moulding…

EPS Machine EPS and…

EPS Machine EPS and…

AEON MINING AEON MINING

AEON MINING AEON MINING

KSD Miner KSD Miner

KSD Miner KSD Miner

BCH Miner BCH Miner

BCH Miner BCH Miner