Automatic Storage Type Determination with Put-away Indicator for Put-away in SAP EWM

- Rajesh Sharma

- Jul 3, 2024

- 2 min read

Automatic Storage Type Determination with Put-away Indicator for Put-away in SAP EWM

This blog will discuss the configuration steps for automatic storage bin determination using the Put-away indicator in SAP Extended Warehouse Management.

Storage Type Search Sequence

Description: The system follows a predefined sequence of storage types to find suitable storage bins.

Use Case: Combines multiple strategies for more flexible put-away.

Configuration:

Define a sequence of storage types.

Configure search sequence and criteria for bin selection.

Configuration Steps

1. Define Storage Types

Step 1: Click On New Entries

Step 2: Enter the Warehouse Number, Storage Type Number, and Description

Step 3: This Storage Type we are going to use without packing so select HU allowed but not mandatory

Put-away Control

- HU Type Check- keep unchecked because not using packed material

- Put-away Rules- 5- Empty Bin

- Addition Stock forbidden

Step 5: Save

2: Define Storage Sections

Step 1: Click on New Entries

Step 2: Enter Storage Type, Storage Section, and Description and Save

3. Define Storage Type Search Sequence for Put-away

Step 1: Click On New Entry

Step 2: Enter Storage Type Search Sequence Name and description and save

4. Assign Storage Type Search Sequence to Storage Type

5. Define Put-away Indicator

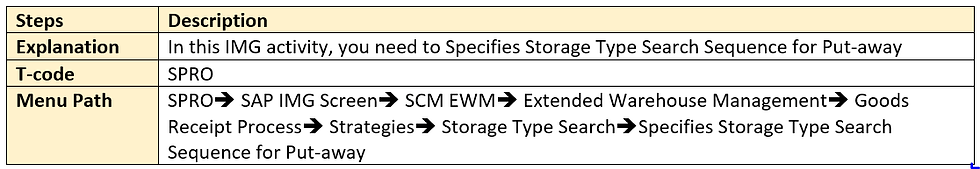

6. Specifies Storage Type Search Sequence for Put-away

7. Optimize Access Strategy for Storage Type Search for Put away

8. Define Storage Bin Structure

9. Generate Activity Area from Storage Type

Step 1: Generate Activity Area from Storage Type

Step 2: Enter Warehouse Number, and Storage Type and click on execute

10. Mass Creation of Storage Bins

Step 1: T-code: /N/SCWM/LS10

Step 2: Select Storage Type Line Item and click on the view button

Step 3: Click on Simulation

Step 4: Click on Create and Save

11. Bin Sorting

Step 1: Enter Warehouse Number

Step 2: Enter the Activity Area and Execute

12. Create Material Master

Step 1: T-code- MM01

Step 2: Enter Material Name, Select Industry and Material Type

Step 3: Select View

Step 4: Enter Organizational Data

13. Enter Plant Storage Location to Material

Step 1: T-code: MMSC

Step 2: Enter Material, and Plant and press enter

Step 3: Enter the Storage Location and Save

14. Maintain Warehouse Product Master

Step 1: T-code: /N/SCWM/MAT1

Step 2: Enter Material, Warehouse Number, Party Entitled to Dispose.

Step 3: Click on Create Button

Step 4: Maintain Put-away Control Indicator in Warehouse Data

15. Assign Storage Bin Type to Storage Type

Test & Validation

Perform test put-away transactions to ensure the system correctly assigns storage bins according to the defined strategy.

Adjust configurations based on test results and operational feedback.

Conclusion

By carefully configuring and implementing these put-away strategies using put-away control indicators, you can significantly improve the efficiency of your warehouse operations in SAP Extended Warehouse Management.

Rajesh Sharma

SAP WM/EWM Functional Consultant

§ Linked in profile: https://www.linkedin.com/in/rajesh-sharma-204910278/

§ Twitter: RajeshS98151512/ RAJESH SHARMA@RAJESHS21287609

§ SAP Blogs: https://www.sastrageek.com/blog

EPS Machine EPS Cutting…

EPS Machine Eps Raw…

EPS Machine EPS Recycling…

EPS Machine EPS Mould;

EPS Machine EPS Block…

EPP Machine EPP Shape…

EPTU Machine ETPU Moulding…

EPS Machine Aging Silo…

EPTU Machine ETPU Moulding…

EPS Machine EPS and…

EPS Machine EPS and…

AEON MINING AEON MINING

AEON MINING AEON MINING

KSD Miner KSD Miner

KSD Miner KSD Miner

BCH Miner BCH Miner

BCH Miner BCH Miner

EPTU Machine ETPU Moulding…

EPTU Machine ETPU Moulding…

EPTU Machine ETPU Moulding…

EPTU Machine ETPU Moulding…

EPTU Machine ETPU Moulding…

EPS Machine EPS Block…

EPS Machine EPS Block…

EPS Machine EPS Block…

AEON MINING AEON MINING

AEON MINING AEON MINING

KSD Miner KSD Miner

KSD Miner KSD Miner

BCH Miner BCH Miner

BCH Miner BCH Miner