S/4HANA Production Planning Integration with MM, FICO, Sales & Distribution Modules

- Rajesh Sharma

- Nov 19, 2024

- 2 min read

The purpose of this blog is SAP S/4 HANA Production Planning & Manufacturing Integration with

Material Management

Finance and Controlling

Sales & Distribution

Production

1. Material Management

1.1 Create Purchasing Group

In this step, you can create and change purchasing groups. A purchasing group can be an individual or a group of individuals

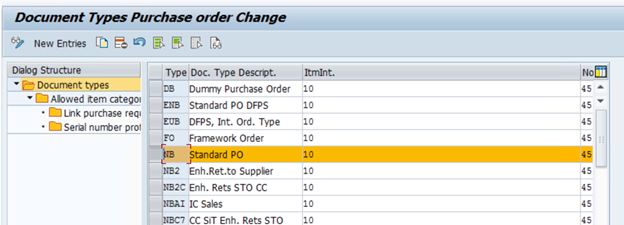

1.2 Define Purchasing Document

Finance Accounting & Controlling

2.1 Define field Status Variant

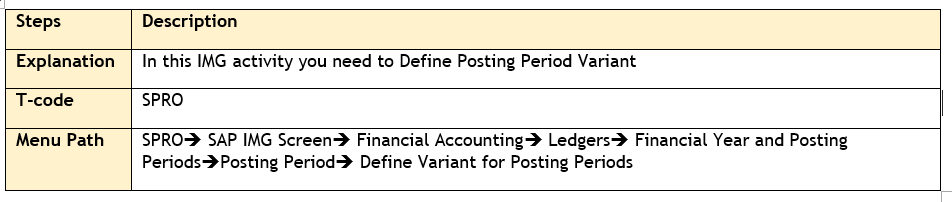

2.2 Define Posting Period Variant

2.3 Open and Close Posting Period

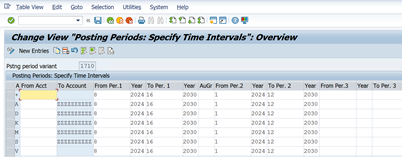

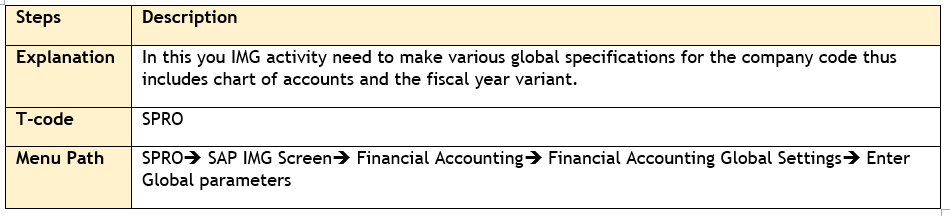

2.4 Enter Global Parameters

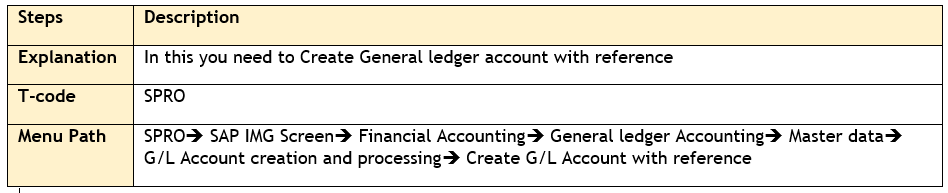

2.5 Create G/L Account with reference

Click on account determination

2.6 Maintain Controlling

3. Material Management

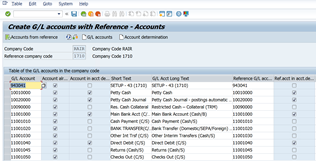

3.1 Configure Automatic Account Determination

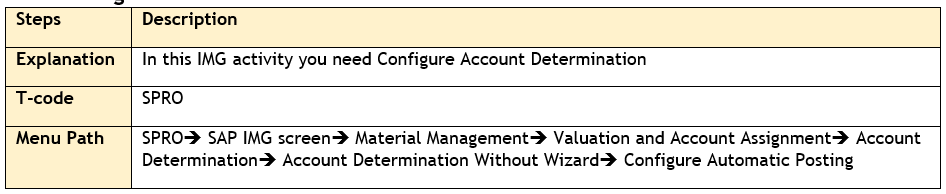

3.2 Define Valuation control

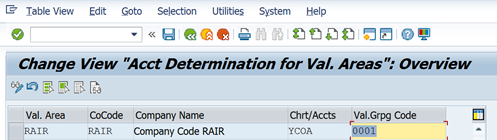

3.3 Group together Valuation area

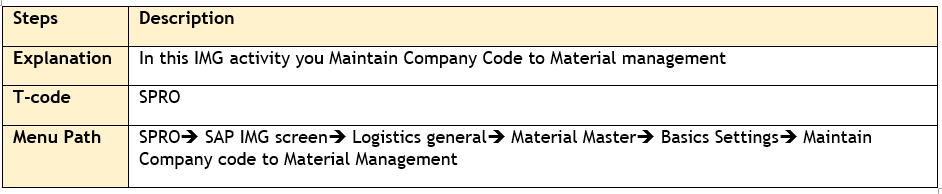

3.3 Maintain Company code to Material Management

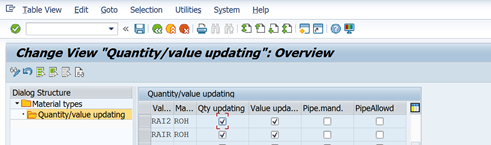

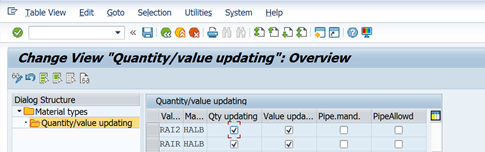

3.4 Define Attributes to Material Type

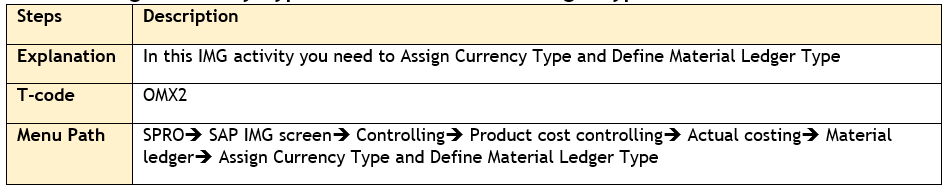

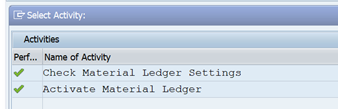

3.5 Assign Currency Type and Define Material Ledger type

3.6 Assign Material Ledger Type to Valuation Area

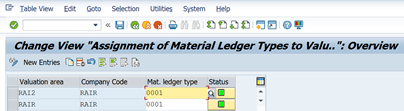

3.7 Activate Material Ledger Type to Valuation Area

Activate Material ledger

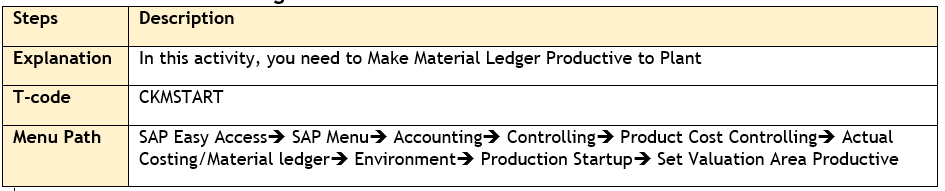

3.7 Make Material Ledger Productive to Plant

Sales & Distribution

4.1 Define Common Distribution channel

4.2 Define Common Division

4.3 Define Sales Document

4.4 Assign Sales Area to Sales Document type

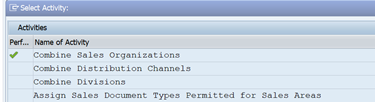

Combine Sales organization

Combine Distribution Channel

Combine Division

Assign Document Type Permitted Sales Area

4.5 Define and Assign Pricing Procedure

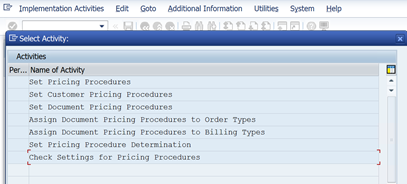

Set Pricing Procedure

Set Customer Pricing Procedure

Set Document Pricing Procedure

Assign Document Pricing Procedure to Order Type

Assign Document Pricing Procedure to Billing Type

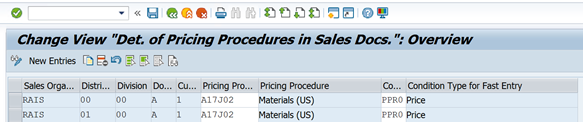

Set Pricing Procedure Determination

4.6 Define Item Category

4.7 Define Item Category Group

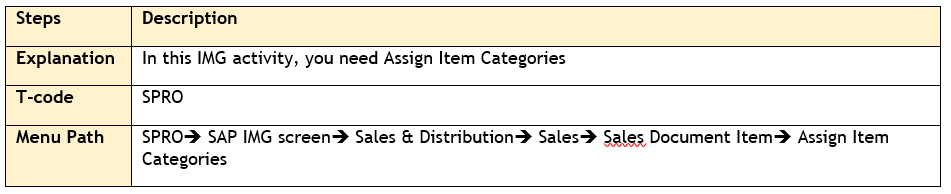

4.8 Assign Item Category

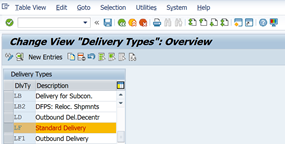

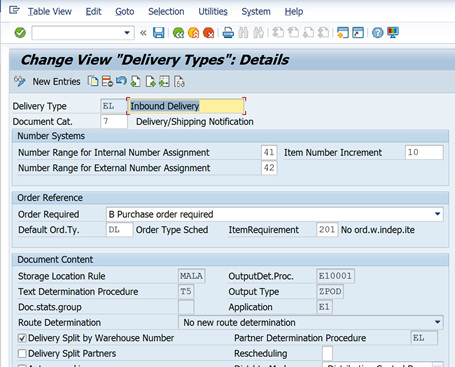

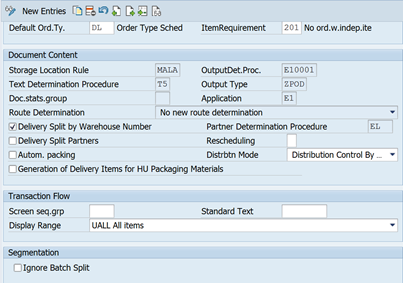

4.9 Define Delivery Type

Production

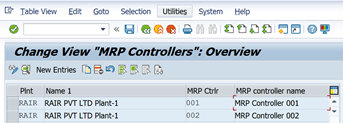

5.1 MRP Controllers

MRP Controllers can be an individual role or group of rules performing the same task. It’s defined based on the role, responsibilities, or area of work instead of individuals.

The MRP controller is primarily responsible for attending to the requirements of materials.

MRP Controller is assigned to MRP 1 view of the material master.

This MRP controller can be used as one of the selection criteria when we run several reports.

Note: MRP Controller is not only used in Production Planning, also used in Procurement Planning in Material Management.

5.2 Capacity Planner

The capacity planner or capacity planner group is responsible for evaluating the current work center or resource capacity. If required leveling of capacity can be performed.

The capacity planners are assigned in the capacity header data of the work center or resource.

This can be utilized as one of the selection criteria in all capacity evaluation & leveling reports.

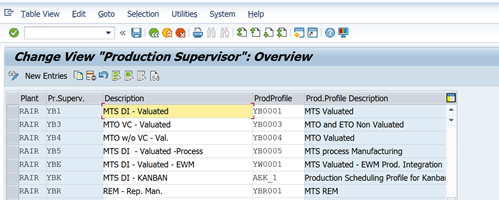

5.3 Production Scheduler

The production scheduler is responsible for ensuring that production execution & operations take place as per the production plan.

Production schedulers can be assigned in the work scheduling view of the material master.

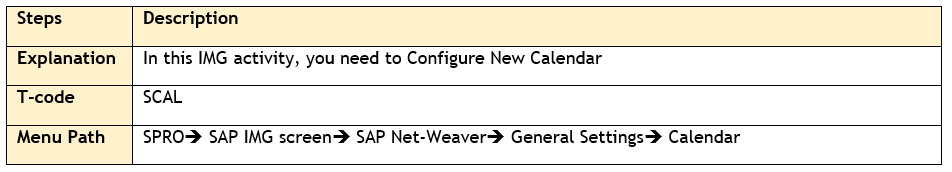

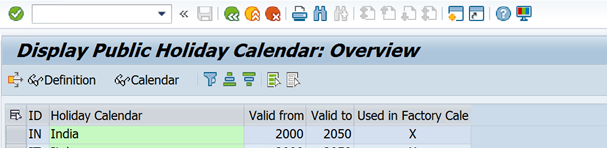

SAP Calendar

For planning & scheduling to effectively take place, it’s imperative that a calendar exists in the system.

This calendar is assigned to the plant.

The SAP Calendar creation function includes three individual steps:

Defining Holidays

Creating holiday calendar

Defining a factory calendar and assigning a holiday calendar to it.

Public Holiday

Holiday Calendar

Factory Calendar

Conclusion

The above steps need to be followed to integrate Production with Material Management, Finance & Controlling, Sales Distribution & Distribution Modules.

Rajesh Sharma

SAP WM/EWM Functional Consultant

§ Linked in profile: https://www.linkedin.com/in/rajesh-sharma-204910278/

§ Twitter: RajeshS98151512/ RAJESH SHARMA@RAJESHS21287609

§ SAP Blogs: https://www.sastrageek.com/blog

I had the opportunity to interact with the customer service team at My Tactical Promos, and I must say, the experience was exceptional. The representatives were not only knowledgeable but also incredibly responsive, addressing my inquiries with precision and clarity. I appreciated the promptness of their replies, which made the entire process seamless and efficient, find customer service contacts on my tactical promos phone number . Additionally, their willingness to go the extra mile to ensure my satisfaction truly stood out. Overall, I felt valued as a customer, and this level of service significantly enhances my confidence in making future purchases. I highly recommend their customer service for anyone seeking a reliable and supportive shopping experience.