Material/Warehouse Product Master Data for Complex Inbound Process using Process-Oriented Storage Control

- Rajesh Sharma

- Jul 14, 2024

- 2 min read

Material/Warehouse Product Master Data for Inbound Process using Process-Oriented Storage Control

This blog will discuss about to prepare material/warehouse product master data for Inbound Process with Process Oriented Storage Control as per the business requirement given below.

Business Requirement

In an Inbound Process Business received a handling unit in which five different products were packed.

As per process flow, the first vehicle reached in warehouse premises, the system automatically determined the inbound warehouse door and unloaded the handling unit that needed to be completed at the door staging area.

After unloading the handling unit needs to be in the goods receipt area.

The received handling unit contained five products that needed to be deconsolidated at the deconsolidation work center.

After deconsolidation at the work center, each product needs to be packed on a new handling unit.

After completion of the packaging of each product, all five products need to complete the final put-away of the product at their respective storage bin.

Put-away strategy is as follows

- Product A- Racking Reserve Storage Area

- Product B- Racking Pick Face Storage

- Product C- Mezzanine Ground Floor

- Product D- Mezzanine 1st Floor

- Product E- Mezzanine 2nd Floor

Required Materials/ Products Master Data

1. Create Material Master

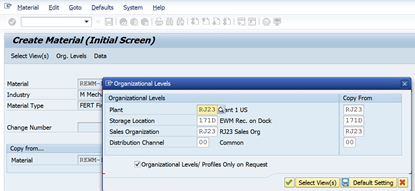

Step 1: T-code: MM01- We need to create five material masters to copy existing material you can create

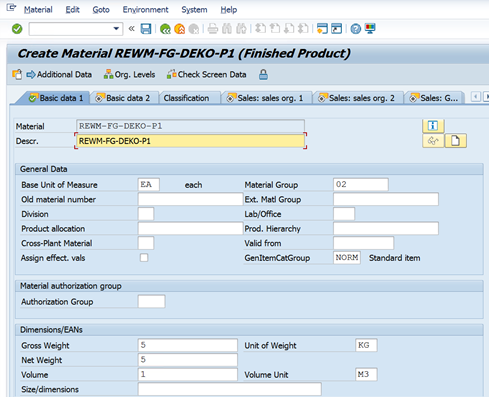

Create Material REWM-FG-DEKO-P1

Select Views

Enter Organizational Data

Basic Data 1

Additional Data

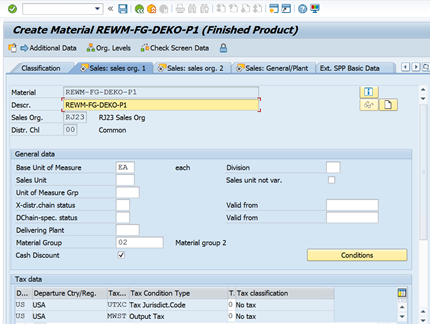

Sales Org Data 1

Sales Org Data 2

Sales General Plant Data

Purchasing data

Plant 2 data

Account 1 Data

WM Packaging Data

Create Using T-code: MM01 REWM-FG-DEKO-P2,

Select Views

Enter Organizational Data

Basic Data 1

Continue Press Enter

Create Using T-code: MM01 REWM-FG-DEKO-P3

Select Views

Enter Organizational Data

Basic Data 1

Continue Press Enter

Create Using T-code: MM01 REWM-FG-DEKO-P4

Select Views

Enter Organizational Data

Basic Data 1

Continue press enter

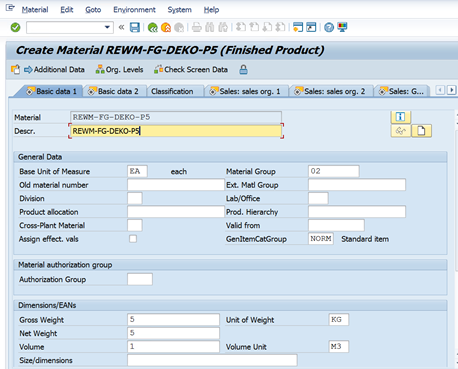

Create Using T-code: MM01 REWM-FG-DEKO-P5

Select View

Enter Organizational Data

Basic data 1

Continue Press Enter

REWM-FG-DEKO-P5 get created

2. Display Material Master

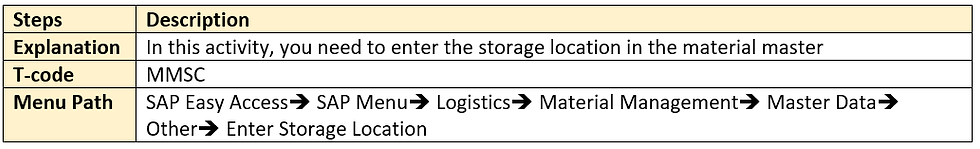

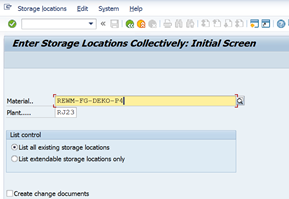

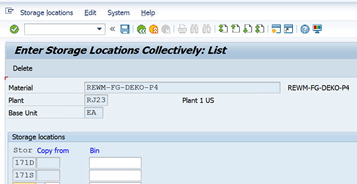

3. Enter Storage Location

Enter Material, Plant

Enter Storage Location, and save

Enter Material, Plant

Enter Storage Location, and save

Enter Material, Plant

Enter Storage Location, and save

Enter Material, Plant

Enter Storage Location, and save

Enter Material and Plant

Enter Storage Location, and save

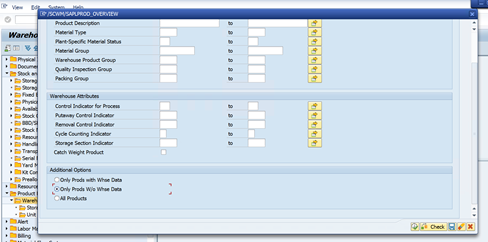

4. Maintain Warehouse Product Master in Mass

Step 1: T-code: /N/SCWM/MON

Step 2: Enter Warehouse Number, Monitor, and Execute

Step 3: Product Master Data==> Warehouse Attributes Search Multiple Materials enter materials and, execute

Step 4: Select radio button only product without warehouse data

Here we can see no warehouse data is maintained

Step 5: Select all products Click on more methods click on mass change/create

Step 6: Click on Execute and Click on Continue

Step 7: Click on Yes

Step 8: Now Click on Warehouse Attribute select the radio button only product with

warehouse data and click on execute

The warehouse product master gets created in mass (for all selected products)

Conclusion

The above steps need to be followed to create materials/ warehouse product masters required for the execution of complex inbound processes using process-oriented storage control.

Rajesh Sharma

SAP WM/EWM Functional Consultant

§ Linked in profile: https://www.linkedin.com/in/rajesh-sharma-204910278/

§ Twitter: RajeshS98151512/ RAJESH SHARMA@RAJESHS21287609

§ SAP Blogs: https://www.sastrageek.com/blog

EPS Machine EPS Cutting…

EPS Machine Eps Raw…

EPS Machine EPS Recycling…

EPS Machine EPS Mould;

EPS Machine EPS Block…

EPP Machine EPP Shape…

EPTU Machine ETPU Moulding…

EPS Machine Aging Silo…

EPTU Machine ETPU Moulding…

EPS Machine EPS and…

EPS Machine EPS and…

AEON MINING AEON MINING

AEON MINING AEON MINING

KSD Miner KSD Miner

KSD Miner KSD Miner

BCH Miner BCH Miner

BCH Miner BCH Miner