Complex Inbound Process with Process-Oriented Storage Control

- Rajesh Sharma

- Jul 21, 2024

- 5 min read

Complex Inbound Process with Process-Oriented Storage Control

This blog will discuss the testing steps for complex inbound processes with process-oriented storage control.

Business Requirement

In an Inbound Process Business received a handling unit in which five different products were packed.

As per process flow, the first vehicle reached the warehouse premises, the system automatically determined the inbound warehouse door and unloaded the handling unit needed at the door staging area.

After unloading the handling unit needs to be in the goods receipt area.

The received handling unit contained five products that must be deconsolidated at the deconsolidation work center.

After deconsolidation at the work center, each product must be packed on a new handling unit.

After completion of the packaging of each product all five products need to complete the final put-away of the product at their respective storage bin.

Put-away strategy is as follows

EWM_REWM_DEKO-P1- Racking Reserve Storage Area

EWM_REWM_DEKO-P2- Racking Pick Face Storage Area

Required Master Data

1. Warehouse Organizational Structure Data

1.1 Storage Type and Storage Bin

Door Storage Type- 9030

Goods Receipt Staging Area- 9010

Deconsolidation Bin- 8010

Rack Storage Type Reserve Area- WHPR

Rack Storage Type Pick Face- WHPF

2. Process-Oriented Storage Control Configuration Steps

2.1 Define External Steps

IB01- Unloading

IB02- Deconsolidation, and Repacking

IB03: Put-away

2.2 Define Storage Process

DEKO- Define Storage Process

2.3 Define Warehouse Process Type

WPT 1011- Deconsolidation Process- Assign Process-Oriented Control- DEKO

WPT 3065- Unloading

WPT 3060- HU Movement

WPT 3040- Repack

2.4 Define Control Indicators for Determining Warehouse Process Type

Process Type Control Indicator- Z1

Determine Warehouse Process Type

2.5 Process-Oriented Storage Control

3. Storage Type Search Sequence and Put-away Control Indicator

Define Storage Type Search Sequence- WHPR, WHPF, MZZF, MZZS

Assign Storage Type Search Sequence- WHPR, WHPF, MZZF, MZZS

Define Put-away Control Indicator- WHPR, WHPF, MZZG, MZZF, MZZS

4. Warehouse Door and Door Determination Group

4.1 Define Staging Areas

INB-STAG-01

4.2 Define Staging Area and Door Determination Group

SADD

4.3 Define Warehouse Door

DRIN

4.4 Assign Staging Area to Door

DRIN-9010-0001

5. Assign Doors to the Supply Chain Unit

Step 1: T-code: /N/SCWM/DOOR_SCU

6. Setting Shipping and Receiving

6.1 Maintain Staging Area and Door Determination (Inbound)

Step 1: T-code: /N/SCWM/STADET_IN

6.2 Access Sequence for Staging Area and Door Determination

Step 2: T-code: /N/SCWM/STADET_ASS

1. Assign Process Type Indicator, Put-away Indicator, Staging Area Door Determination Group to Warehouse Product Master

Step 1: T-code: /N/SCWM/MON

Test & Validation

Perform test Deconsolidation of HU which has multiple products in it in EWM and packed each product on separate Handling Unit put-away transactions to ensure the system correctly assigns storage bins according to the defined strategy.

Adjust configurations based on test results and operational feedback.

Complex Inbound Delivery Process Flow

1. Creation Purchase Order

Step 1: Enter Vendor, Purchase Organization, Purchasing Group, and Company Code in Organizational data at header view

Step 2: Enter Material, Quantity, Unit of Measure, Price, Per Unit, Currency, Receiving Plant, and Storage Location

Step 3: Select 04 Inbound Delivery at the confirmation tab and save.

Purchase order4500004570 Created

2. Creation LE Inbound Delivery

Step 1: Enter the Vendor, Purchase Order Number and External Identification and press enter

Step 2: Select line Item and Click on Pack button

Step 3: Enter Packaging Material and Press Enter HU Created

Step 4: Select HU line Item and All Material Line Item and Click on Pack Button

HU Packed with 2 Line Item

Step 5: Click on Save, Inbound Delivery Document 180002165 Created and Distributed in WMS

3. Display LE Inbound Delivery

Step 1: Enter Inbound Delivery Document 180002165 and press Enter

Step 2: Click on the Goods Movement tab

Goods Movement Not Started, Click on Pack Button

Step 3: Click on the Pack Button

One HU Contains 2 Items

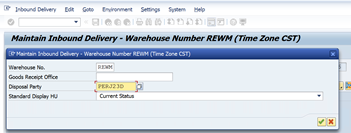

4. Maintain Inbound Delivery in EWM

Step 1: Select Document Type from Dropdown, ERP Inbound Delivery Document, Enter Inbound Delivery Document Number and Execute

Step 2: Click on Form View at the Delivery Header level

Here We can see the Delivery Document Number, Document Category, Document Type, GR office, ASN, and Goods Receipt. Unloading, Put-away Status Not Started.

Step 3: Select all line Item and Click on Form view

Item details of Each Line Item

Movement Data

Status and Shipping Conditions

Click on HU tab

5. Create a Warehouse Task from the Warehouse Monitor

Step 1: Enter the Warehouse Number, Monitor, and Execute

Step 2: Enter LE Delivery Document Number, and Click on Execute

Step 3: Click on Inbound Delivery Item, and More Methods, click on Create Warehouse Task in Background

Click on Warehouse Task tab

Step 4: Select Open Warehouse Task and Click on More Methods and Click on Confirm Warehouse Task in Background

As the 3065 IB01 Unloading Task Confirmed,

The 3060 HU Put-away task was Created and appears in open status Source Storage Type 9010 and Destination Storage Type 8010

Step 5: Confirm Put-away Task in back Ground

Now we can see HU move from Staging Area to Deconsolidation Bin

6. Check Inbound Delivery Status

Step 1: Enter the Delivery Document number and Execute

Here we can see that Unloading and Goods Receipt were completed and Put-away Status has not started yet

7. Deconsolidation In Goods Receipt

Step 1: Enter the Warehouse Number, Work Center, HU Number, and Execute

Step 2: Click on the Deconsolidate Tab, Enter Source HU, and click on warehouse tasks, select warehouse task, and click on continue

Step 3: Enter Packaging Material, and Execute

Repeat the above steps for next warehouse task

Step 5: Select all HUs and Click on Complete HU and Save

8. Confirm Task for IB03 Put-away

Step 1: Enter Warehouse Number, Monitor and Execute

Step 2: Enter LE Delivery Document Number, and Click on Execute

Step 3: Click on Inbound Delivery Item, and Warehouse Task tab

We can find here Put-away task gets changed from waiting status to open status

Material HU now moved from Deconsolidation bin to WHPF Storage Bin

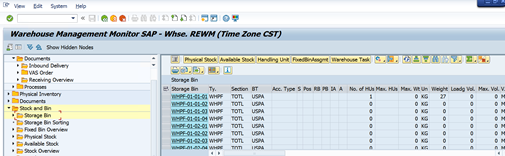

9. Stock Overview in the Warehouse

Step 1: Enter Warehouse Number, Monitor, and Execute

Step 2: Storage Bin, Physical Stock, Enter Materials, and Execute

Here we can see Stock of materials

10. Material Document List

Step 1: Enter Materials

Step 2: Plant, Storage Location, and Execute

Here we can status of stock and materials document

11. Display Inbound Delivery in S/4HANA

Step 1: Enter Delivery Document Number and press enter

Step 2: Click on Goods Movement tab here we can see goods movement Status get completed

Step 3: Click on Document Flow

Goods receipt document and storage location to storage location transfer document get created

Display GR Goods Receipt Document, and click on Document Info, then click on FI Document

View Accounting Document

Actual Cost Document

Material Ledger

Display Storage location to Storage Location Transfer Document

Click on FI Document this the Material Transfer Storage Location to Storage Location with in same plant no FI Document Generated

Conclusion

The above steps need to be followed for the Complex Inbound Process with Deconsolidation and repacking the product and final put-away of each product in their respective storage bins which will be determined automatically as per storage type search sequence.

Rajesh Sharma

SAP WM/EWM Functional Consultant

§ Linked in profile: https://www.linkedin.com/in/rajesh-sharma-204910278/

§ Twitter: RajeshS98151512/ RAJESH SHARMA@RAJESHS21287609

§ SAP Blogs: https://www.sastrageek.com/blog

EPS Machine EPS Cutting…

EPS Machine Eps Raw…

EPS Machine EPS Recycling…

EPS Machine EPS Mould;

EPS Machine EPS Block…

EPP Machine EPP Shape…

EPTU Machine ETPU Moulding…

EPS Machine Aging Silo…

EPTU Machine ETPU Moulding…

EPS Machine EPS and…

EPS Machine EPS and…

AEON MINING AEON MINING

AEON MINING AEON MINING

KSD Miner KSD Miner

KSD Miner KSD Miner

BCH Miner BCH Miner

BCH Miner BCH Miner

EPS Machine EPS Cutting…

EPS Machine Eps Raw…

EPS Machine EPS Recycling…

EPS Machine EPS Mould;

EPS Machine EPS Block…

EPP Machine EPP Shape…

EPTU Machine ETPU Moulding…

EPS Machine Aging Silo…

EPTU Machine ETPU Moulding…

EPS Machine EPS and…

EPS Machine EPS and…

AEON MINING AEON MINING

AEON MINING AEON MINING

KSD Miner KSD Miner

KSD Miner KSD Miner

BCH Miner BCH Miner

BCH Miner BCH Miner